PUR Hot Melt Adhesive vs. Standard Hot Melt Adhesive for Edge Banding: Key Advantages

When it comes to edge banding, choosing the right hot melt adhesive is crucial for achieving a durable, high-quality finish. Among the various adhesive options, PUR (Polyurethane Reactive) hot melt adhesive stands out as a superior choice compared to standard hot melt adhesives. This article explores the key advantages of PUR hot melt adhesives for edge banding applications.

1. Superior Bond Strength

One of the most significant advantages of PUR hot melt glue is their exceptional bonding strength. PUR adhesives form strong bonds with a variety of substrates, including wood, MDF, and particleboard. This strength ensures that the edge banding remains securely attached, even under stress, making it ideal for high-demand applications.

Comparison:

PUR Adhesive: Strong, durable bond suitable for high-stress environments.

Standard Hot Melt: Adequate adhesion, but may not hold up as well under stress.

2. Enhanced Moisture Resistance

Moisture resistance is critical in edge banding, especially in environments with fluctuating humidity. PUR glue excel in this area, providing a robust barrier against moisture that prevents peeling and delamination over time.

Comparison:

PUR Adhesive: Highly moisture-resistant, ideal for humid environments.

Standard Hot Melt: Less effective against moisture, leading to potential failures.

3. High Heat Resistance

PUR adhesives maintain their bond strength even at elevated temperatures, ensuring reliability in heat-sensitive applications. This feature is particularly beneficial for products exposed to heat, such as kitchen cabinetry.

Comparison:

PUR Adhesive: Retains adhesion at high temperatures.

Standard Hot Melt: May lose adhesion when exposed to heat.

4. Flexibility and Durability

PUR hot melt adhesives provide a flexible bond, allowing them to absorb movement and changes in temperature without cracking. This flexibility is essential for wood products that may expand or contract over time.

Comparison:

PUR Adhesive: Flexible, durable bond that accommodates movement.

Standard Hot Melt: Often more rigid, risking cracks and separation.

5. Effective Curing Process

PUR hot melt adhesives cure through moisture in the air, resulting in a strong, durable bond. This curing process allows for longer open times, enabling more precise application and adjustments during bonding.

Comparison:

PUR Adhesive: Longer open time for adjustments and precise application.

Standard Hot Melt: Quick setting time, which may limit adjustability.

6. Environmental Resistance

In addition to moisture and heat resistance, PUR adhesives offer better resistance to chemicals and environmental factors. This quality makes them suitable for demanding applications where exposure to harsh conditions is a concern.

Comparison:

PUR Adhesive: Superior resistance to chemicals and environmental factors.

Standard Hot Melt: Less resistant, limiting usability in certain conditions.

7. Lower VOC Emissions

Many PUR hot melt adhesives have lower volatile organic compound (VOC) emissions compared to traditional hot melts. This makes them a more environmentally friendly option, contributing to a healthier workspace.

Comparison:

PUR Adhesive: Generally lower VOC emissions, more eco-friendly.

Standard Hot Melt: Higher VOC emissions, which may raise safety concerns.

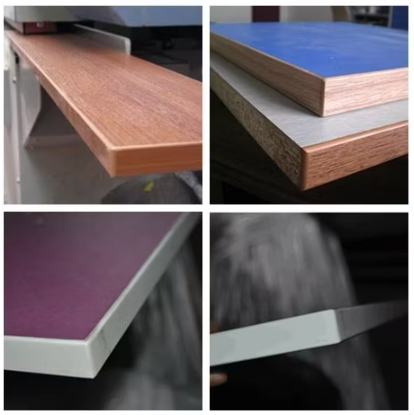

8. Aesthetic Finish

PUR adhesives provide a cleaner finish with less visible glue lines, enhancing the overall appearance of the finished product. This aesthetic quality is particularly important in high-end applications where appearance matters.

Comparison:

PUR Adhesive: Cleaner finish with minimal glue lines.

Standard Hot Melt: May produce more visible glue lines.

Conclusion

In conclusion, PUR hot melt adhesives offer numerous advantages over standard hot melt adhesives in edge banding applications. With their superior bond strength, moisture and heat resistance, flexibility, and lower environmental impact, PUR adhesives are the go-to choice for achieving high-quality, durable edge banding. When selecting an adhesive for your next project, consider the benefits of PUR hot melt adhesives for optimal results. For more insights and recommendations on hot melt adhesives, please feel free to CONTACT US Confay adhesive a professional adhesive supplier! Our professional team of technical solution will be your strongest back up.